Cervical plates and screws, essential medical devices in spinal surgery, find specific use in procedures concerning the cervical spine, which comprises seven vertebrae (C1 to C7). The cervical spine consists of seven vertebrae labeled C1 through C7, and it plays a crucial role in supporting the head, allowing for head movement, and protecting the spinal cord.

Crafting Cervical Plates and Screws In modern medicine, intricate tools enhance healthcare outcomes, including cervical plates and screws revolutionizing spinal surgery. These components offer stability to the cervical spine, aiding healing. Let’s explore their materials and manufacturing process.

Craftsmanship Behind Cervical Plates and Screws

In the world of modern medicine, intricate tools and devices play a pivotal role in enhancing healthcare outcomes. One such innovation that has revolutionized spinal surgery is the development of cervical plates and screws.

These small yet crucial components provide stability and support to the cervical spine, aiding in the healing and recovery process. But have you ever wondered about the craftsmanship that goes into creating these medical marvels? Let’s delve into the world of cervical plates and screws, exploring their materials and the meticulous manufacturing process behind them.

Materials: The Foundation of Excellence

Experts design and craft cervical plates and screws meticulously, ensuring they can withstand the mechanical stresses and biological conditions within the human body. The choice of materials is critical in ensuring the devices’ longevity, biocompatibility, and structural integrity. The most common material used for cervical plates and screws is titanium, and for good reason.

Titanium: This lightweight and strong metal has become the gold standard in medical device manufacturing. Its biocompatibility ensures that the body doesn’t reject the implant, reducing the risk of adverse reactions. Additionally, titanium’s corrosion resistance and ability to integrate with bone during the healing process make it an ideal choice for spinal implants.

Manufacturing Process: Engineering Precision

Creating cervical plates and screws requires a blend of engineering precision, medical expertise, and advanced manufacturing techniques. Here’s an overview of the manufacturing process:

Design and Prototyping: Medical device manufacturers work closely with orthopedic surgeons and engineers to design cervical plates and screws that address specific medical needs. Medical professionals use computer-aided design (CAD) software to create intricate 3D models, enabling accurate representation and the ability to make modifications.

Material Selection: As mentioned earlier, titanium is the preferred material due to its exceptional properties. Subsequently, the selected titanium alloy undergoes processing to guarantee its purity and structural integrity.

Machining and Fabrication: The manufacturing process begins with precision machining. Computer numerical control (CNC) machines cut, shape, and form the titanium material into the desired screw and plate designs. This step demands exceptional precision to ensure the final product’s reliability.

Surface Treatment: Titanium surfaces can be modified to enhance bone integration. Techniques like sandblasting, acid etching, or applying bioactive coatings are employed to encourage osseointegration, where bone naturally grows around the implant.

Quality Control: Rigorous quality control measures are applied throughout the manufacturing process. Each cervical plate and screw undergoes thorough inspections to ensure dimensions, tolerances, and surface finishes meet exacting standards.

Sterilization and Packaging: Once the components are fabricated and inspected, they undergo sterilization processes to ensure they are free from pathogens.

Following the sterilization process, the plates and screws undergo meticulous packaging within sterile environments, making them prepared for distribution and utilization in surgical procedures.

Different Types of Cervical Plates

Several cervical plate types, frequently employed in surgical procedures, include:

-

Adjustable Occipital Plates:

Titanium plates, adjustable for personalized fit. This allows surgeons to customize the fit of the plate to the individual patient’s anatomy, which can help to improve stability and reduce the risk of complications.

-

Anterior Cervical Plate (ACP):

Frontal placement for ACDF procedures. ACPs typically have screw holes for fixation into the vertebral bodies and may incorporate locking mechanisms to prevent screw backout. You can get more information about Anterior Cervical Plate System.

-

Occifix Plates:

Fixed titanium plates for severe instability.

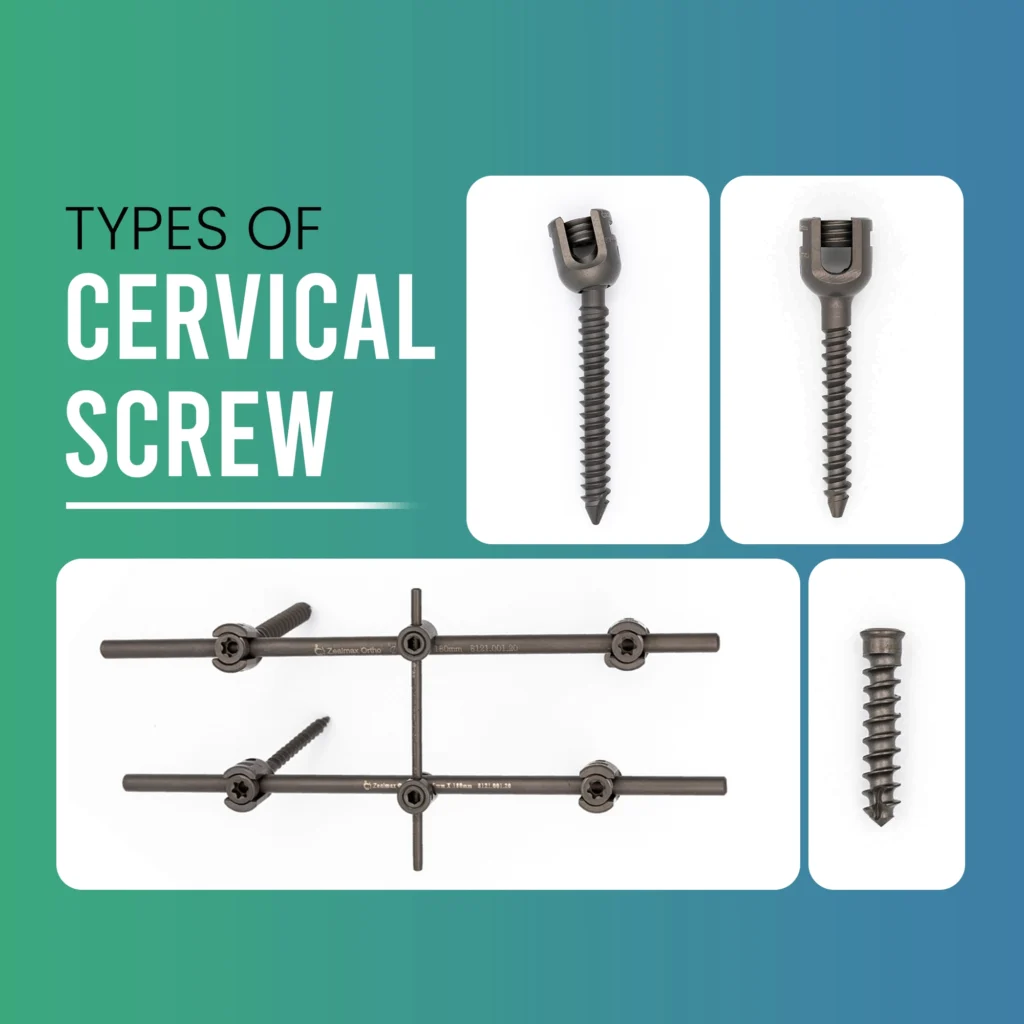

Different Types of Cervical Screw

The screws used in cervical spine surgery can vary in design and function. Some common spine screw types include:

-

Pedicle Screws:

They provide strong anchorage and stability, often used in posterior cervical fusion surgeries. Read more on .

-

Lateral Mass Screws:

These screws are inserted into the lateral masses of the vertebrae.

-

Cortical Screws:

These screws are designed for fixation in the thin outer layer of bone, the cortical bone.

-

Variable-Angle Screws:

These screws have variable angulation, allowing the surgeon to adjust the screw trajectory for optimal fixation and stability.

-

Locking Screws:

Locking screws have a mechanism that locks them securely into the plate, reducing the chances of screw loosening over time.

Fusing Medicine and Engineering

Cervical plates and screws stand as a testament to the seamless integration of medical science and engineering innovation. These devices, crafted with precision from advanced materials, contribute significantly to improving the quality of life for individuals undergoing spinal surgery. Their careful design, selection of biocompatible materials, and meticulous manufacturing process highlight the interdisciplinary collaboration required to bring groundbreaking medical solutions to life.

As medical technology continues to evolve, the craftsmanship behind cervical plates and screws serves as a reminder of the remarkable feats achievable when medical professionals and engineers work hand in hand to push the boundaries of possibility.

Zealmax Ortho: A Renowned Manufacturer of Cervical Plates and Screws

With the same level of trust and confidence that a well-established brand enjoys, Zealmax Ortho’s cervical plates and screws are making a significant impact across the globe! Our state-of-the-art facility located in India stands as one of the largest and best-equipped in the country.

We design and offer an extensive range of cervical plates and screws in titanium adhering to the highest industry standards and norms. Our journey has propelled us to the forefront of the cervical plates and screws industry as a premier manufacturer and supplier.

Conclusion

Zealmax Ortho, hailing from India, stands as a reliable manufacturer, supplier, and exporter of orthopedic implants. Currently commemorating over a decade of excellence, we have proudly provided top-tier trauma orthopedic implants since 2006. Our journey has been remarkable, marked by the presence of a committed team of experts with specialized manufacturing and supply experience in the realm of Orthopedic implants. Operating in 60 countries worldwide, Zealmax has unquestionably established a respected position for itself in the global industry.